About Us

A complete manufacturing solutions provider from design to assembly

Rooted in Dongguan, Guangdong, a major Chinese manufacturing hub, we specialize in precision metal stamping, CNC machining, assembly & prototyping. We reliably serve industries like communications electronics, automotive, appliances, and smart devices.

Strategically located in the Greater Bay Area core, we offer convenient logistics, robust industrial clusters, and highly responsive supply chains.

Corporate Vision

To be a leading global partner in precision manufacturing

Corporate Values

Quality ⋅ Innovation ⋅ Integrity ⋅ Agility

Service

Manufacturing Capabilities

We offer one-stop service from product design to production and then to delivery. The design stage is professional and innovative, with full support from the mold center. We have strong production capacity, and surface treatment and pattern customization are flexible. We strictly control quality and standardize packaging, warehousing and transportation processes to ensure high-quality product delivery.

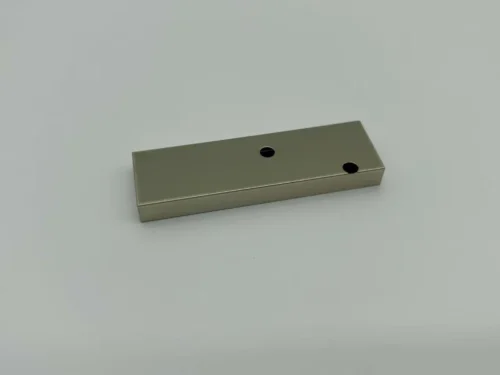

product

Our Products

Our Strength

Corporate Advantages

Precision Manufacturing Capability

Equipped with advanced stamping, CNC machining, and auxiliary equipment to deliver precision parts ranging from tiny components to large structural assemblies.

Customized Solutions

Offering design optimization and process adjustments tailored to clients’ specific requirements, helping them overcome R&D and production challenges.

Comprehensive Quality System

Strictly following ISO quality management systems with full-process inspection to ensure consistent quality and reliability.

Fast Response & On-Time Delivery

Flexible production scheduling and an efficient team to handle urgent orders and ensure short lead times.

One-Stop Service

Covering tooling, stamping, CNC machining, finishing, assembly, and packaging in one integrated solution to save clients time and cost.

Global Partnership Experience

Over a decade of export experience, working with clients from Europe, America, and Asia, familiar with international standards.

factory

Environmental Display

partner

Our Customers

Struggling with complex manufacturing needs?

- 90% of clients launch projects within 48 hours after consultation

- Average 30% cost reduction achieved for 100+ clients.