Technology Way

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio. Hendrerit turpis leo dapibus massa in. Integer hac ut leo malesuada ornare.

Full inspection-assembly-packaging

Six “8-meter” full inspection/assembly lines operate in parallel, and each line is equipped with an independent inspection station to achieve a closed loop of the “inspection-assembly-packaging” process. The daily production capacity of a single line can reach 5,000 pieces.

Two “21-meter” long intelligent assembly lines achieve seamless connection of the entire process, flexibly adapt to multi-specification production, accurately synchronize processes, increase daily production capacity by 50%, and achieve a product yield of more than 99%.

The production line station can quickly change models (changeover time ≤ 30 minutes), supporting small batch and multi-variety production. Support multi-line collaborative production, urgent orders are delivered within 72 hours, and meet customers’ JIT (just-in-time) supply needs.

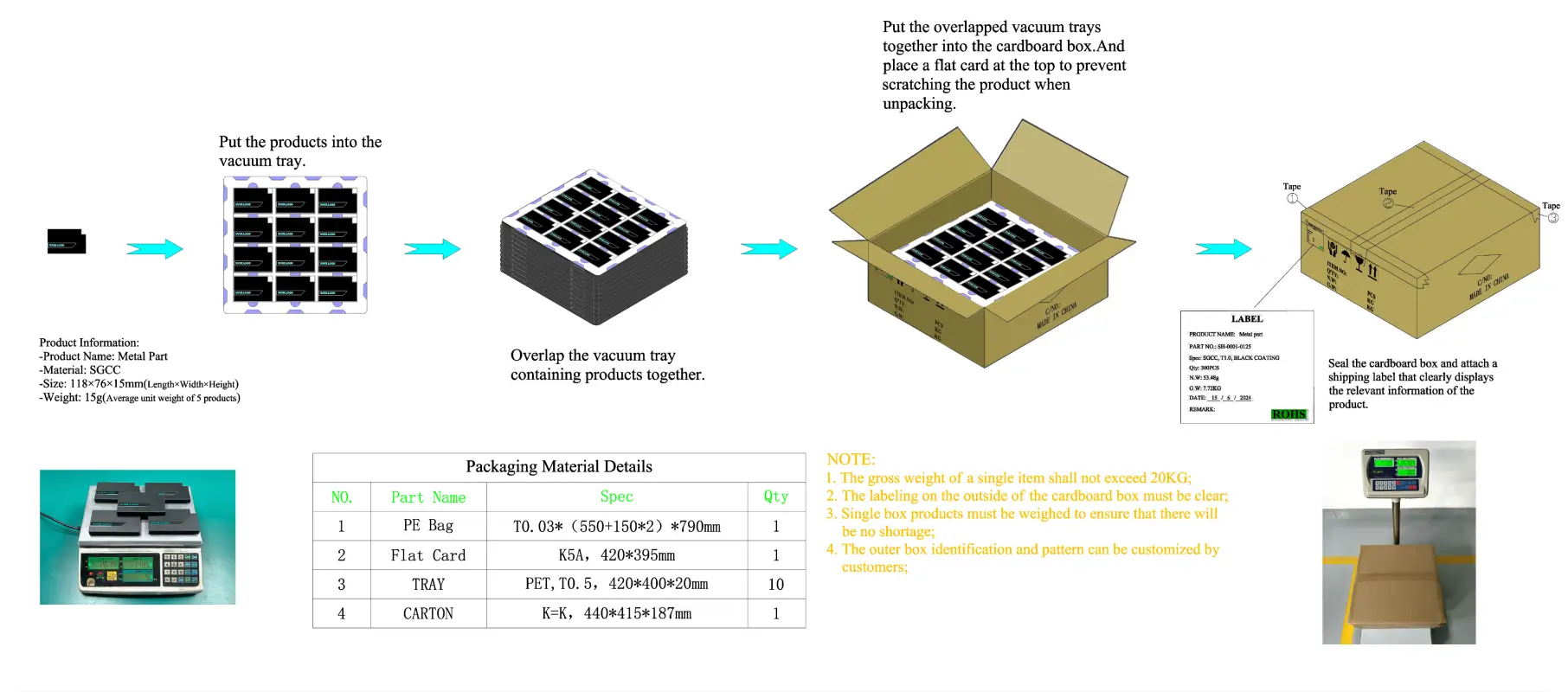

Packaging Line

Assembly Line

Packaging method: Blister Tray