Technology Way

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio. Hendrerit turpis leo dapibus massa in. Integer hac ut leo malesuada ornare.

Research & Design

After receiving the customer’s order, we will purchase the corresponding raw materials and auxiliary materials, and formulate a production plan to ensure the order is delivered on time. Our production team has rich experience in different manufacturing processes, such as stamping, CNC, and tapping. They will work together to ensure that the produced parts meet customer requirements.

Stamping Part Design

CNC Part Design

Stimnlation Part Design

Jig Disignoy

Stamping Part Design

CNC Part Design

Stimnlation Part Design

Jig Disignoy

Mold Center

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio. Hendrerit turpis leo dapibus massa in. Integer hac ut leo malesuada ornare.

Mold Center

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio. Hendrerit turpis leo dapibus massa in. Integer hac ut leo malesuada ornare.

Upload Drawings

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio.

DFM Analysis

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio.

Mold Design

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio.

Mold Processing

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio.

Submit Sample

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio.

Trial Mold

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio.

Mould Assembly

Lorem ipsum dolor sit amet consectetur. A bibendum pretium lectus nunc. Massa nisl vulputate vel sagittis odio.

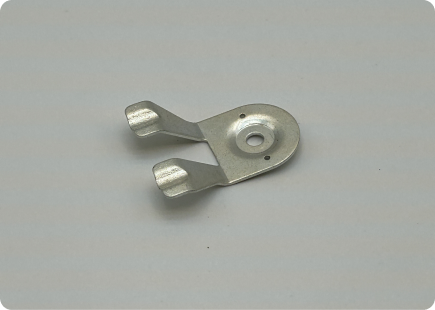

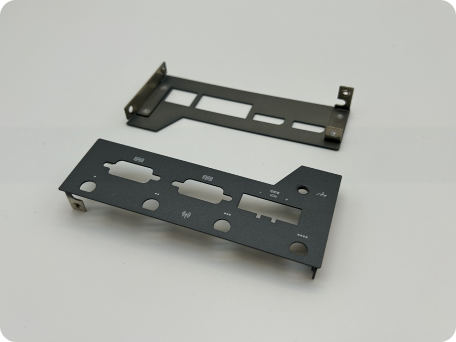

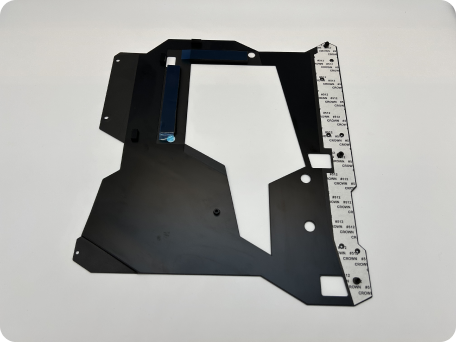

Production and processing

After receiving the customer’s order, we will purchase the corresponding raw materials and auxiliary materials, and formulate a production plan to ensure the order is delivered on time. Our production team has rich experience in different manufacturing processes, such as stamping, CNC, and tapping. They will work together to ensure that the produced parts meet customer requirements.

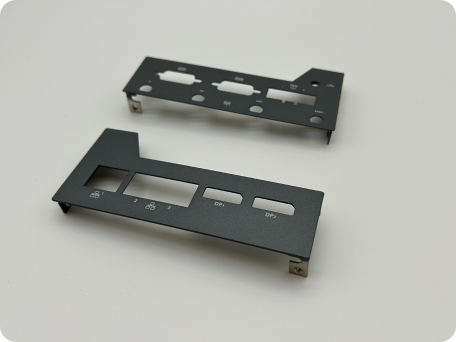

Surface treatment

Surface treatment is a process that uses the four core values of protection, strengthening, beautification and functionalization to artificially form a surface layer on the surface of the base material that has different mechanical, physical and chemical properties from the base material. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product.

| Process Type | Applicable Scenarios | Core Advantages | Typical Cases | *** *** |

|---|---|---|---|---|

| Plating | Applicable Scenarios | Core Advantages | Typical Cases | *** *** |

| Anodizing | Applicable Scenarios | Core Advantages | Typical Cases | *** *** |

| Powder Roasted | Applicable Scenarios | Core Advantages | Typical Cases | *** *** |

| Liquid Baking | Applicable Scenarios | Core Advantages | Typical Cases | *** *** |

| Electrophoresis | Applicable Scenarios | Core Advantages | Typical Cases | *** *** |

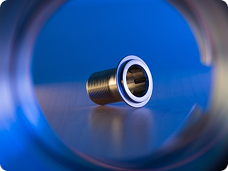

Electroplating products

Anodizing

Powder roasted

Liquid Baking

Electrophoresis

Pattern customization

Common ways to customize patterns on product surfaces include screen printing, pad printing, UV printing, laser engraving and other processes. Customized surface patterns are a key process to enhance product value. Their functions include accurate information transmission (functional identification), brand enhancement and product identification (commercial value), functional guidance and operation optimization (human-computer interaction), surface decoration and texture enhancement (aesthetic value). They are widely used in consumer electronics, automotive parts, industrial equipment, home appliances and other fields.

网印

移印

UV 印刷

雪雕

蚀刻

Electroplating products

Anodizing

Powder roasted

Liquid Baking

Electrophoresis

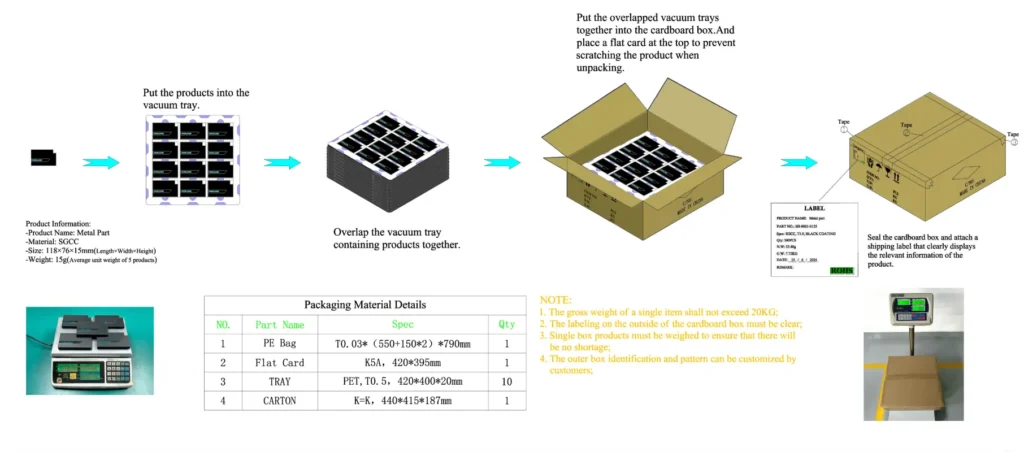

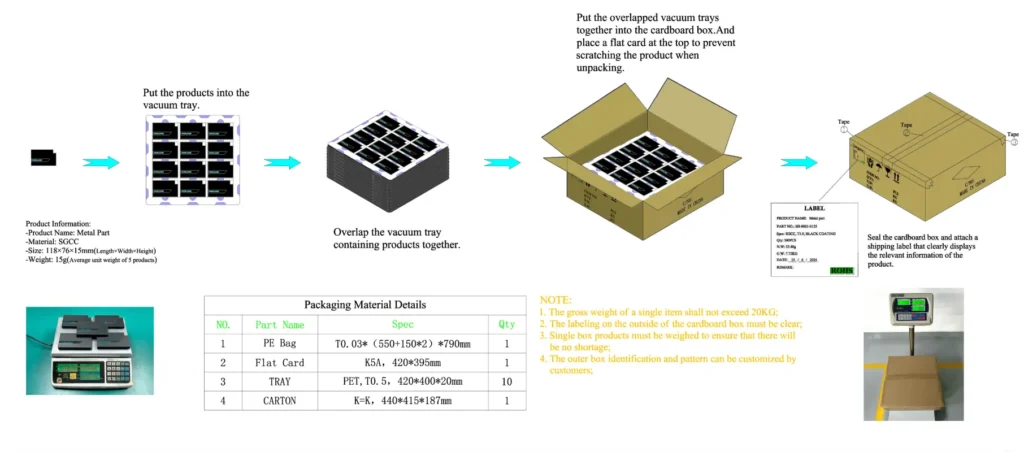

Full inspection-assembly-packaging

Six “8-meter” full inspection/assembly lines operate in parallel, and each line is equipped with an independent inspection station to achieve a closed loop of the “inspection-assembly-packaging” process. The daily production capacity of a single line can reach 5,000 pieces.

Two “21-meter” long intelligent assembly lines achieve seamless connection of the entire process, flexibly adapt to multi-specification production, accurately synchronize processes, increase daily production capacity by 50%, and achieve a product yield of more than 99%.

The production line station can quickly change models (changeover time ≤ 30 minutes), supporting small batch and multi-variety production. Support multi-line collaborative production, urgent orders are delivered within 72 hours, and meet customers’ JIT (just-in-time) supply needs.

Packaging Line

Assembly Line

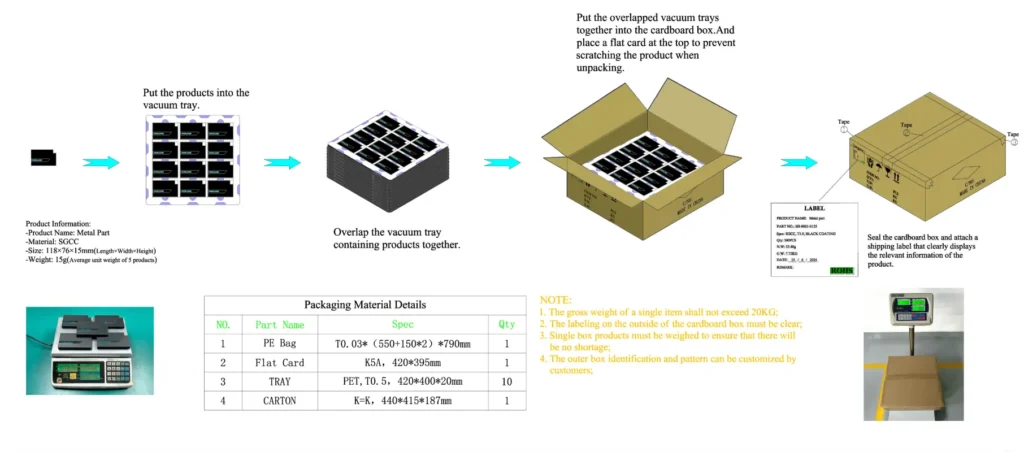

Packaging method

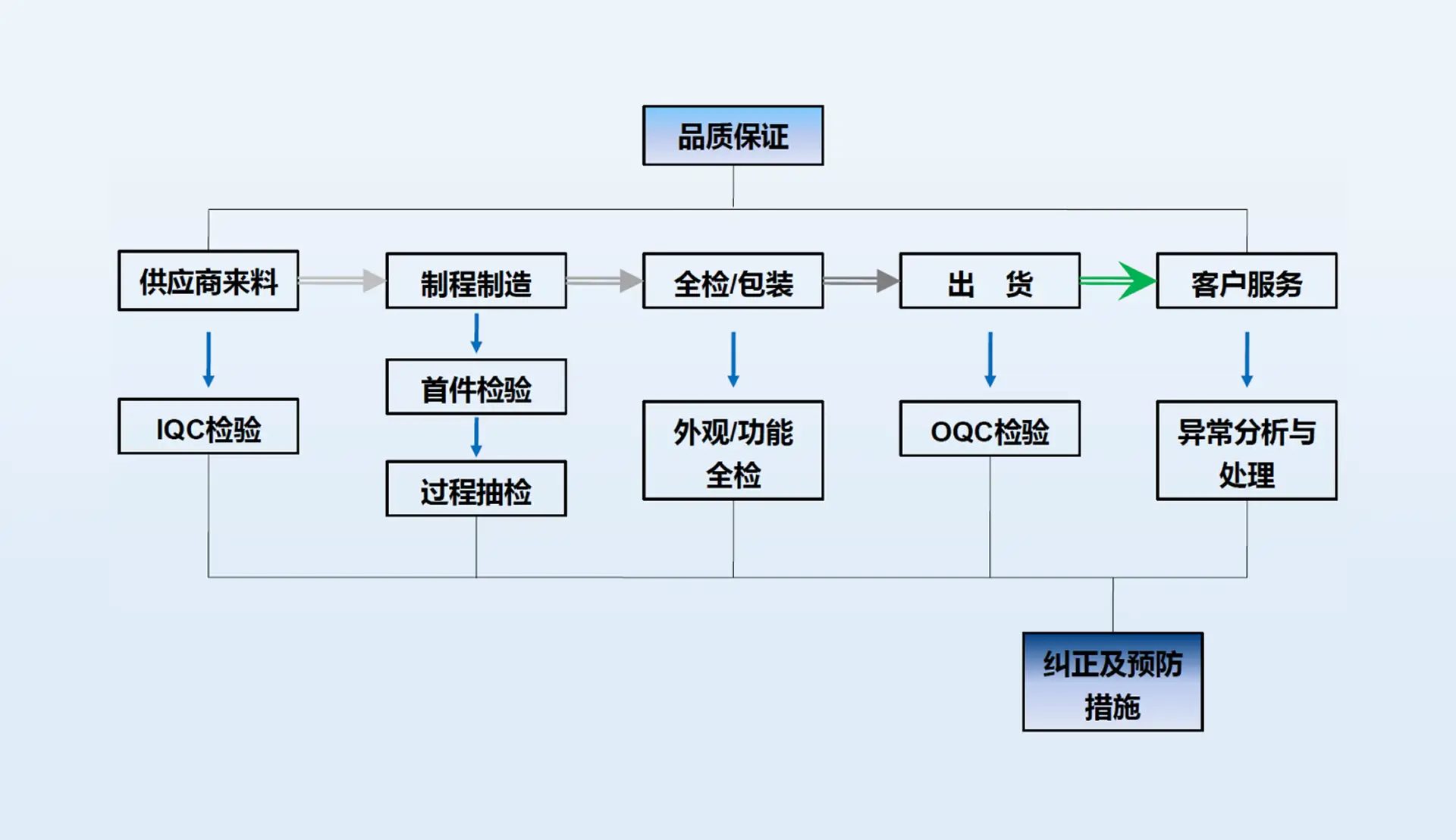

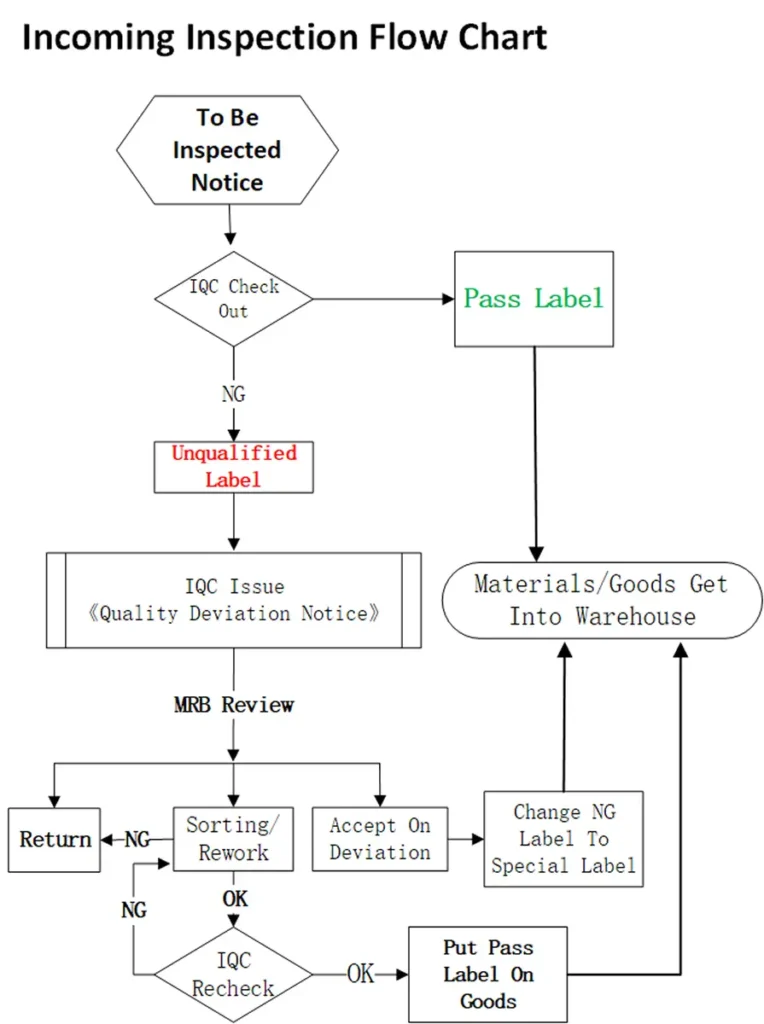

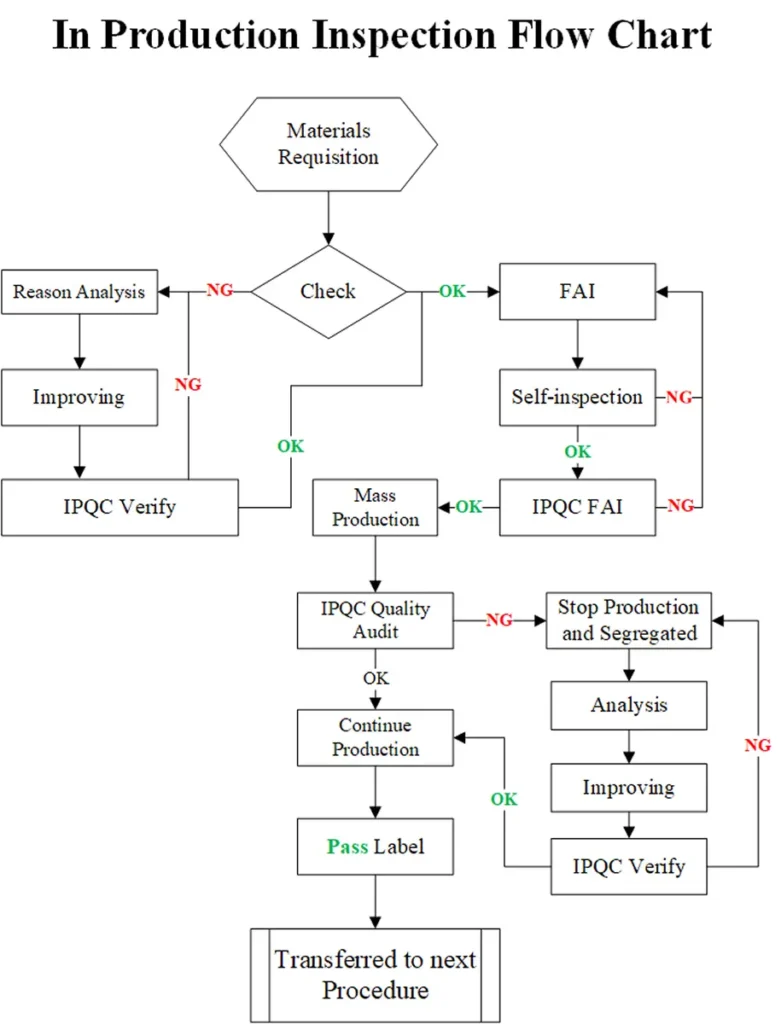

Quality Control

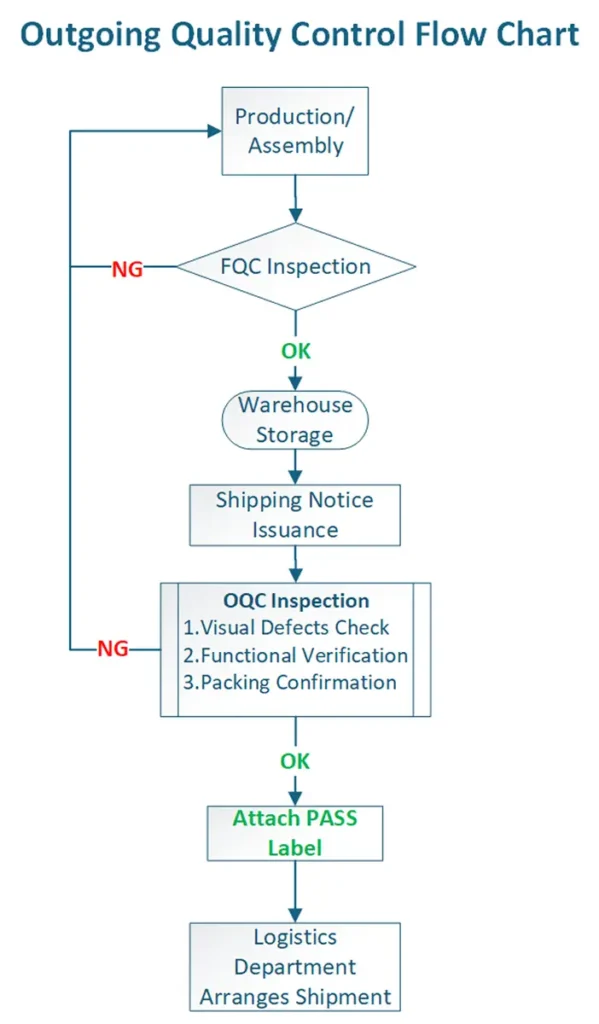

From the entry of raw materials to the exit of finished products, we have set up four major quality inspection nodes to conduct all-round quality monitoring of the production process to ensure that the quality of each link is controllable. We strictly implement ISO standards and support customers to inspect goods at the factory, so that customers can rest assured about the product quality and enhance their trust in the company.

Fast Lead Time

Fast Lead Time

Fast Lead Time

Fast Lead Time

Fast Lead Time

Fast Lead Time

Fast Lead Time

Fast Lead Time

Warehousing

Lorem ipsum dolor sit amet consectetur. Eu blandit at vitae metus egestas id scelerisque eget tincidunt. Turpis risus tellus tincidunt morbi enim semper ut tellus. Neque a in in volutpat. Est tristique faucibus sagittis sapien sagittis dictum. Amet non condimentum lectus at tempor vitae lacus a nunc. Faucibus vel mauris convallis dolor sed. Dolor massa sapien egestas amet felis placerat ut porttitor vitae.

transportation

Lorem ipsum dolor sit amet consectetur. Eu blandit at vitae metus egestas id scelerisque eget tincidunt. Turpis risus tellus tincidunt morbi enim semper ut tellus. Neque a in in volutpat. Est tristique faucibus sagittis sapien sagittis dictum. Amet non condimentum lectus at tempor vitae lacus a nunc. Faucibus vel mauris convallis dolor sed. Dolor massa sapien egestas amet felis placerat ut porttitor vitae.