Pattern Customization

Common ways to customize patterns on product surfaces include screen printing, pad printing, UV printing, laser engraving and other processes. Customized surface patterns are a key process to enhance product value. Their functions include accurate information transmission (functional identification), brand enhancement and product identification (commercial value), functional guidance and operation optimization (human-computer interaction), surface decoration and texture enhancement (aesthetic value). They are widely used in consumer electronics, automotive parts, industrial equipment, home appliances and other fields.

Pattern Marking Method

| Method | Key Advantages | Applications | Performance Tests | Environmental Compliance |

|---|---|---|---|---|

| Screen Printing | Bright colors, cost-effective, ideal for mass production | Plastic casings, panels, buttons, nameplates | Adhesion, abrasion, alcohol wipe | Solvent ink contains VOC |

| Pad Printing | Works on irregular surfaces, flexible | 3C products, buttons, curved parts | Adhesion, friction, humidity resistance | Depends on ink type |

| UV Printing | High precision, quick drying, weather-resistant | Decorative patterns, branding logos, premium electronics | Adhesion, UV resistance, scratch test | Low-VOC UV ink |

| Laser Marking | Permanent, fade-resistant, high durability | Serial numbers, QR codes, logos | Abrasion, clarity test | No ink or consumables |

| Etching | Fine details, textured finish, capable of deep etching | Metal nameplates, panels, decorative finishes | Salt spray, film thickness, adhesion | Acid handling required |

Screen Printing

Pad Printing

UV Printing

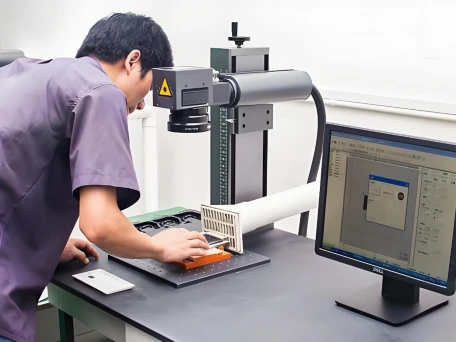

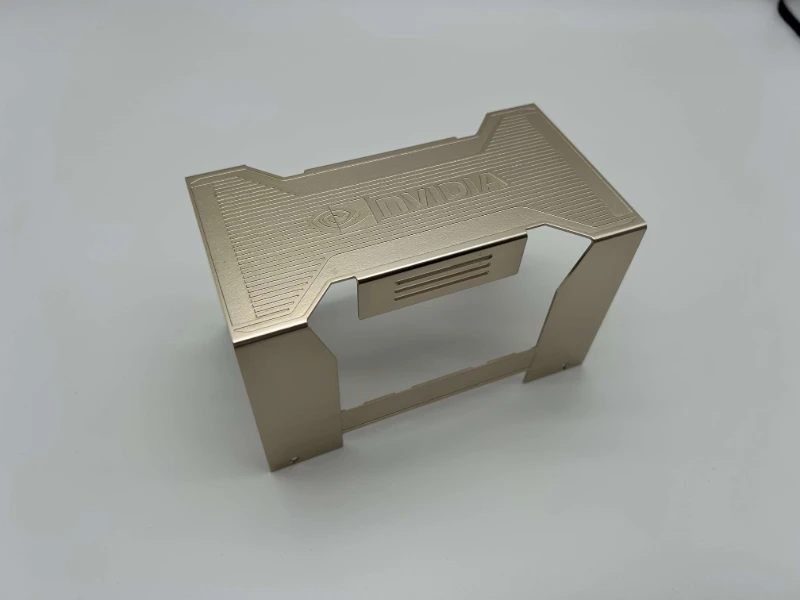

Laser Marking

Etching

Screen Printed Product

Etched Product

Pad Printed Product

Laser Marked Product