Mold Center

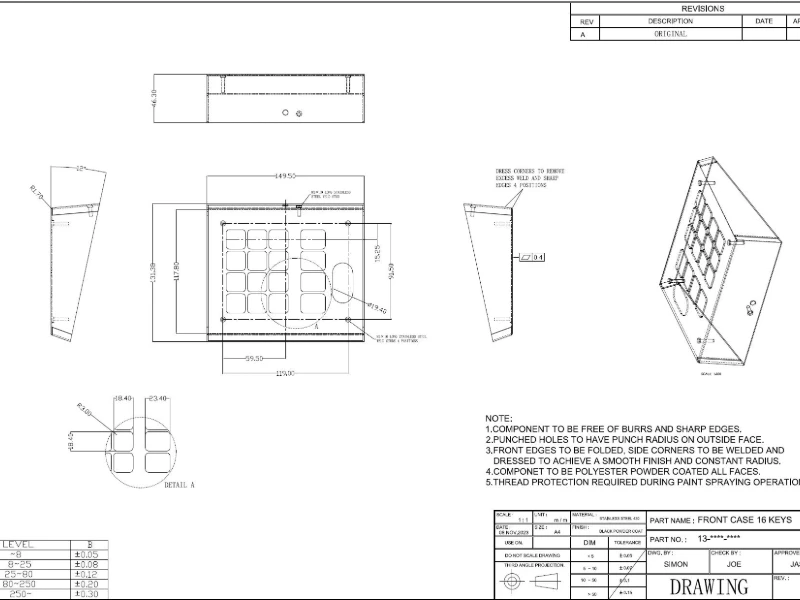

1. Upload Drawings

The process begins with the client submitting product design drawings, which set the foundation and specify all technical requirements.

2. DFM Analysis

A Design for Manufacturability analysis is conducted to assess the feasibility of molding and suggest optimizations for better quality and cost-effectiveness.

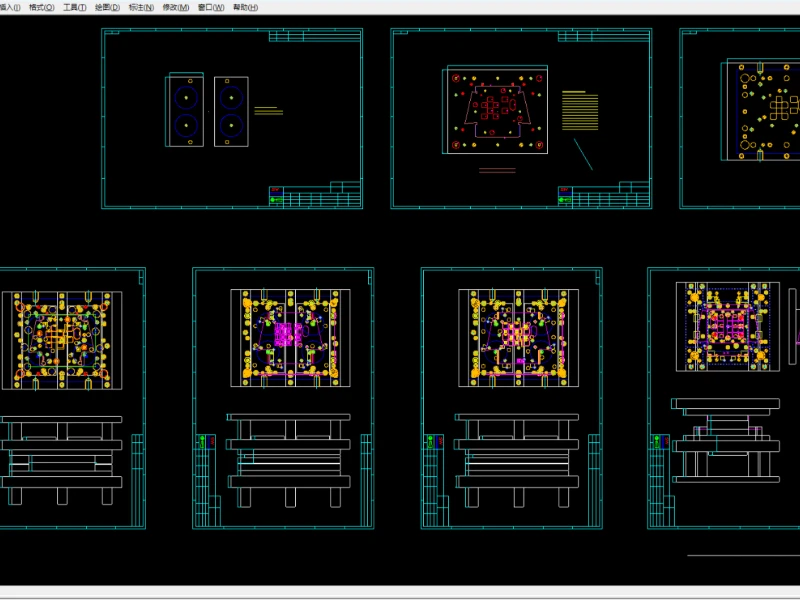

3. Mold Design

Detailed mold structure is designed based on the final design, producing the machining drawings.

4. Mold Processing

Mold steel is precision-machined into components and parts using equipment like CNC and EDM according to the design drawings.

7. Submit Sample

Upon successful trial and meeting client requirements, qualified samples are submitted for approval, completing the mold development process.

6. Mold Trial

Initial trials are run on an molding machine to check performance, sample dimensions, and defects, making necessary adjustments.

5. Mold Assembly

All machined parts (core, cavity, sliders, ejector pins, etc.) are carefully assembled and debugged to ensure precise fit and functionality.