Production Capacity

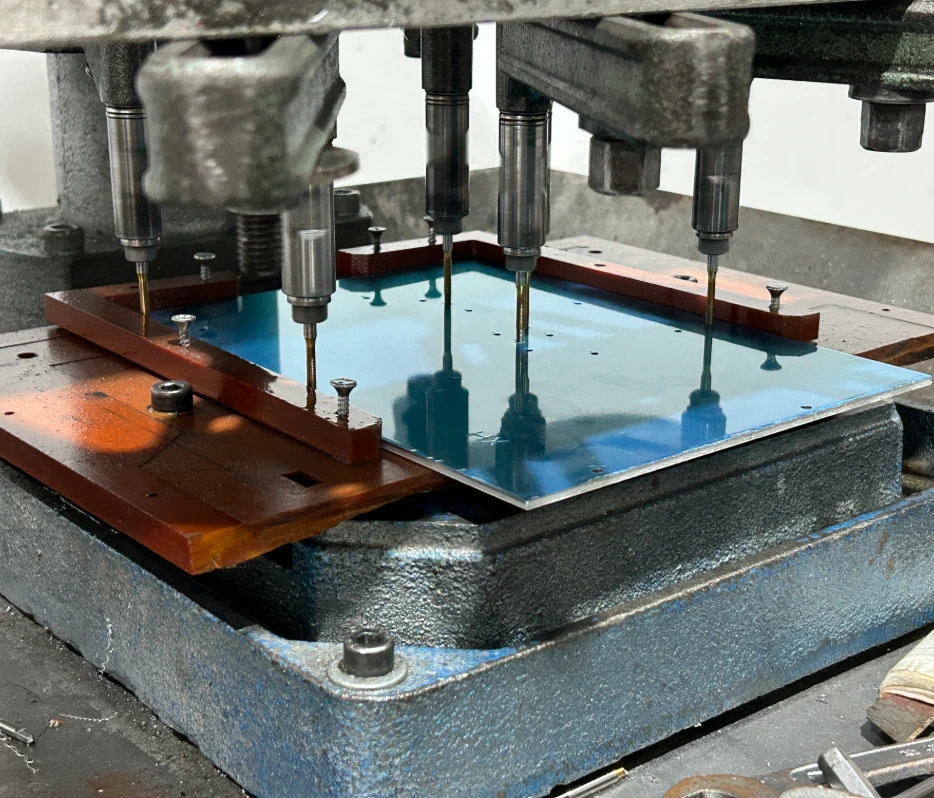

We are equipped with advanced production facilities and over 50 high-precision machines, including stamping presses, CNC machines, tapping, welding, and riveting equipment, ensuring high efficiency and accuracy. Our stamping handles complex large-scale parts, while CNC machining ensures tight tolerances.

We process a wide range of metals—iron, aluminum, stainless steel, and copper—offering customized solutions for both mass production and small batches. Materials are flexibly managed to meet diverse industry needs efficiently.

Upon receiving orders, we source materials, plan production, and leverage our experienced team to ensure parts meet strict standards and are delivered on time.

Order Confirmation

• Customer places an order, Sales team confirms requirements, specifications, and quantity.

• Order information is entered into the system and an order number is generated.

Material Preparation

• Check inventory according to order requirements.

• Purchase missing raw materials or semi-finished products.

• Conduct incoming quality inspection.

Production Planning

• Schedule production lines and processes.

• Arrange shifts according to delivery deadlines.

• Generate production plan.

Manufacturing

• Perform stamping, CNC machining, welding, assembly, and other processes.

• Conduct in-process quality control during production.

• Record production data to ensure traceability.

Progressive Stamping

CNC Machining

CNC Lathe

Welding

Tapping

Riveting

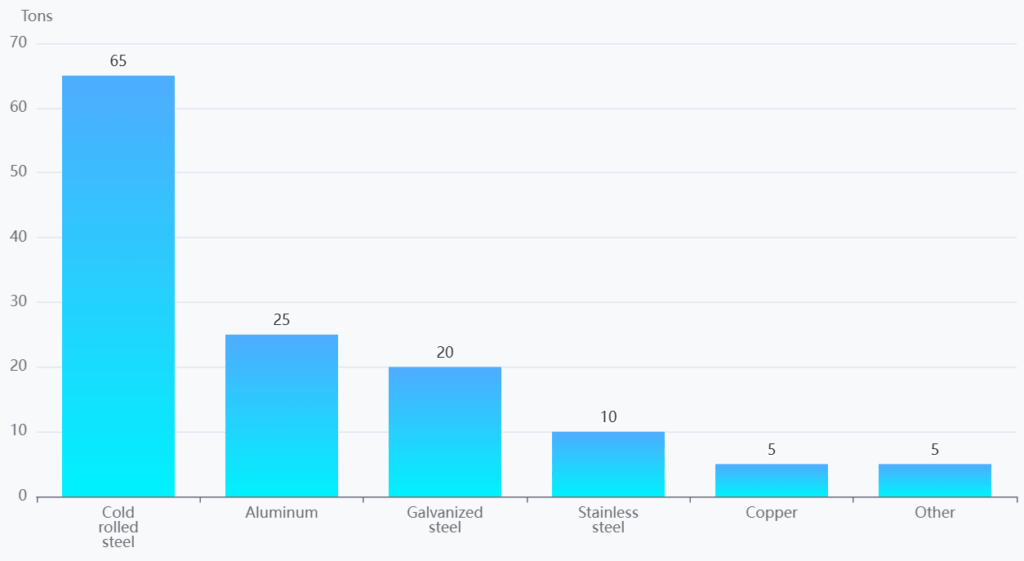

Average Monthly Usage of Materials

Main Equipment List

| Equipment Name | Brand / Manufacturer | Model | Quantity | Processing Capability | Precision | Remarks |

|---|---|---|---|---|---|---|

| Punching Machine (200T Single Crank) | SEYI | NC1-200 | 10 / pcs | Max pressure 200T | ±0.05 mm | With auto feeder |

| Punching Machine (200T Double Crank) | SEYI | JH21-200D | 5 / pcs | For large die operations | ±0.05 mm | |

| Punching Machine (300T) | SEYI | NC1-300 | 2 / pcs | For large part stamping | ±0.05 mm | |

| Punching Machine (400T) | SEYI | SN1-400 | 1 / pcs | Heavy-duty stamping | ±0.05 mm | |

| Punching Machine (160T / 110T) | SEYI | JH21 Series | 20 / pcs | For small-medium components | ±0.05 mm | Some with auto feeder |

| High-speed Press | Chin Fong | CHS-80/ 110/ 160 | 6 / pcs | High-speed up to 400 spm | ±0.02 mm | For small precision parts |

| CNC Machining Center | FANUC | Robodrill | 6 / pcs | XYZ travel: 700x400x400 mm | ±0.01 mm | Suitable for batch precision work |

| Tapping Machine | Local | Custom | 4 / pcs | Auto tapping M3-M10 | ±0.05 mm | For thread processing |

| Spot Welding Machine | Panasonic | SPW-35 | 3 / pcs | For sheet metal welding | N/A | Manual operation |

| Coordinate Measuring Machine (CMM) | Mitutoyo | CMM-574 | 1 / pcs | Measuring range 500x700x400 mm | ±0.005 mm | High-precision inspection |